Circuit boards are the foundation of modern electronics, silently working behind the scenes to keep our devices running. They form the backbone of everything from smartphones to household appliances. By connecting components like resistors, capacitors, and microchips, they ensure that electrical signals flow precisely where needed. Without them, many of the technologies we rely on daily wouldn’t exist. Understanding how circuit boards function is key to appreciating the intricate systems that power our digital and physical worlds.

What is a Circuit Board?

Circuit boards, often referred to as printed circuit boards (PCBs), are the essential platforms upon which modern electronic devices operate. They provide a framework for connecting electronic components, ensuring electrical signals travel seamlessly. Imagine them as the “highways” of electronic systems, directing currents between components like resistors, capacitors, and microcontrollers. Every smartphone, computer, or appliance owes its functionality to these intricate boards. But what are they made of, and how do they differ? Let’s dive deeper.

Basic Structure of Circuit Boards

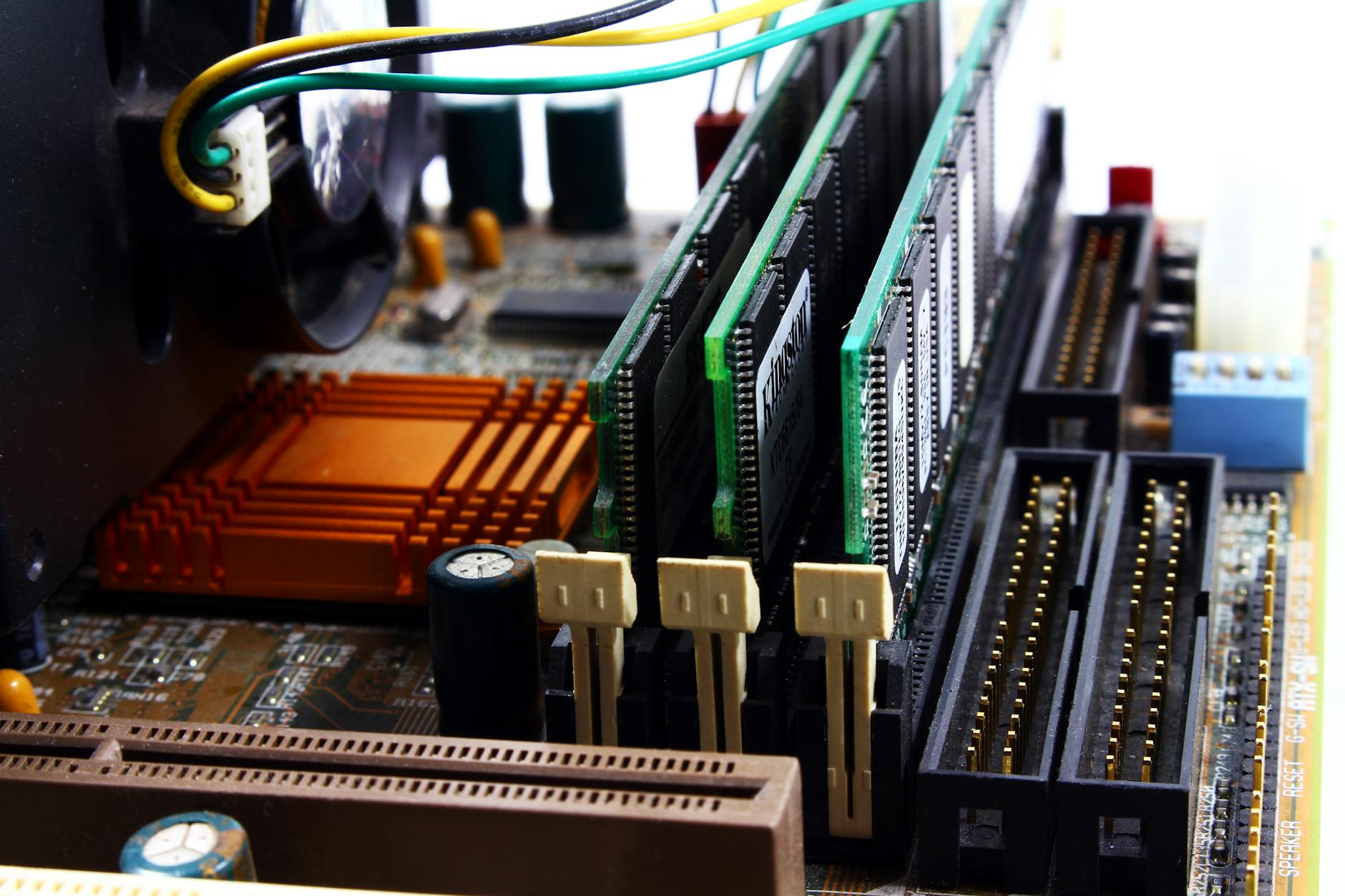

Circuit boards might look like a chaotic mix of lines and components, but their structure has a purpose. They are composed of four fundamental layers, each with distinct roles:

- Substrate: This is the base material that gives the circuit board its rigidity. Made from fiberglass or epoxy resin, the substrate ensures the board holds its shape while resisting heat and physical strain.

- Copper Layer: Sitting above the substrate, this layer conducts electricity. Thin strips of copper are etched to form conductive pathways that link the components together. Without this layer, electrical signals wouldn’t flow between parts.

- Solder Mask: This layer is added on top of the copper to prevent accidental contact between traces, which could result in short circuits. Usually green, the solder mask also provides some protection against environmental factors like moisture or dust.

- Silkscreen: The topmost layer contains printed labels, symbols, and text. It helps engineers, assemblers, and repair technicians identify components and connections on the board.

Each layer complements the others to ensure a circuit board performs reliably. Together, these layers create a unified platform capable of hosting even the most complex electronic designs.

Learn more about how PCBs are designed and their importance here.

Types of Circuit Boards and Their Uses

Circuit boards come in several variations, each tailored to specific applications. While they all share the same foundational principles, their designs address differing technical needs and use cases.

- Single-Layer PCBs: As the name implies, these boards consist of just one layer of copper conducting paths. They are cost-effective and ideal for simpler devices like calculators and LED lights.

- Double-Layer PCBs: These boards double the conductive capacity by incorporating copper layers on both sides of the substrate. This makes them suitable for moderately complex devices like amplifiers and power supplies.

- Multi-Layer PCBs: Containing more than two layers of copper, these are used in high-performance electronics. From laptops to communication devices, multi-layer boards handle complex routing and higher signal speeds.

- Flexible PCBs: Built on bendable materials, these boards can conform to unusual shapes. Widely used in medical devices, wearable technology like smartwatches, and even flexible phones, they offer versatility and durability.

- Rigid-Flex PCBs: Combining the benefits of both flexible and rigid boards, these are often seen in aerospace and military applications, where weight and compactness are critical.

- High-Frequency PCBs: Designed for signal processing at higher frequencies, these boards often appear in satellite systems, radar equipment, and cellular base stations.

The right type of PCB is chosen based on the technical demands of the application it serves. For a deeper understanding of how PCBs support electronics, check out this detailed introduction.

How Circuit Boards Work

Circuit boards are the unsung heroes of modern electronics, orchestrating the precise flow of electricity that powers countless devices. But how do these intricate systems function? By exploring the essential mechanics, we can grasp how circuit boards ensure seamless performance, connecting components into a cohesive whole.

Tracing the Flow of Electricity

Electricity travels like a current down a carefully laid path on a circuit board, much like cars following designated lanes on a highway. These paths, known as traces, are made of thin copper and are integral to guiding electrical signals. Each trace connects different components, such as transistors, resistors, and capacitors, enabling the circuit to function as intended.

Here’s how the journey unfolds:

- Power Source Connection: The circuit board receives power, often from a battery or direct power line.

- Signal Flow Through Traces: Copper traces carry the electrical current across the board. These traces can look like a complex maze when viewed up close, but each path serves a clear purpose.

- Component Activation: As electricity moves, it powers components like transistors (for amplifying signals), capacitors (for storing and releasing energy), and resistors (for controlling current levels).

- Current Return: After completing its task, the electrical current makes its way back to the source, forming a closed loop.

To put it simply, the circuit board acts like a post office for electricity—routing signals to their proper destinations with precision.

For a detailed breakdown of how copper traces and other elements interact, check out this explanation on PCBs and their parts.

The Role of Soldering in Circuit Boards

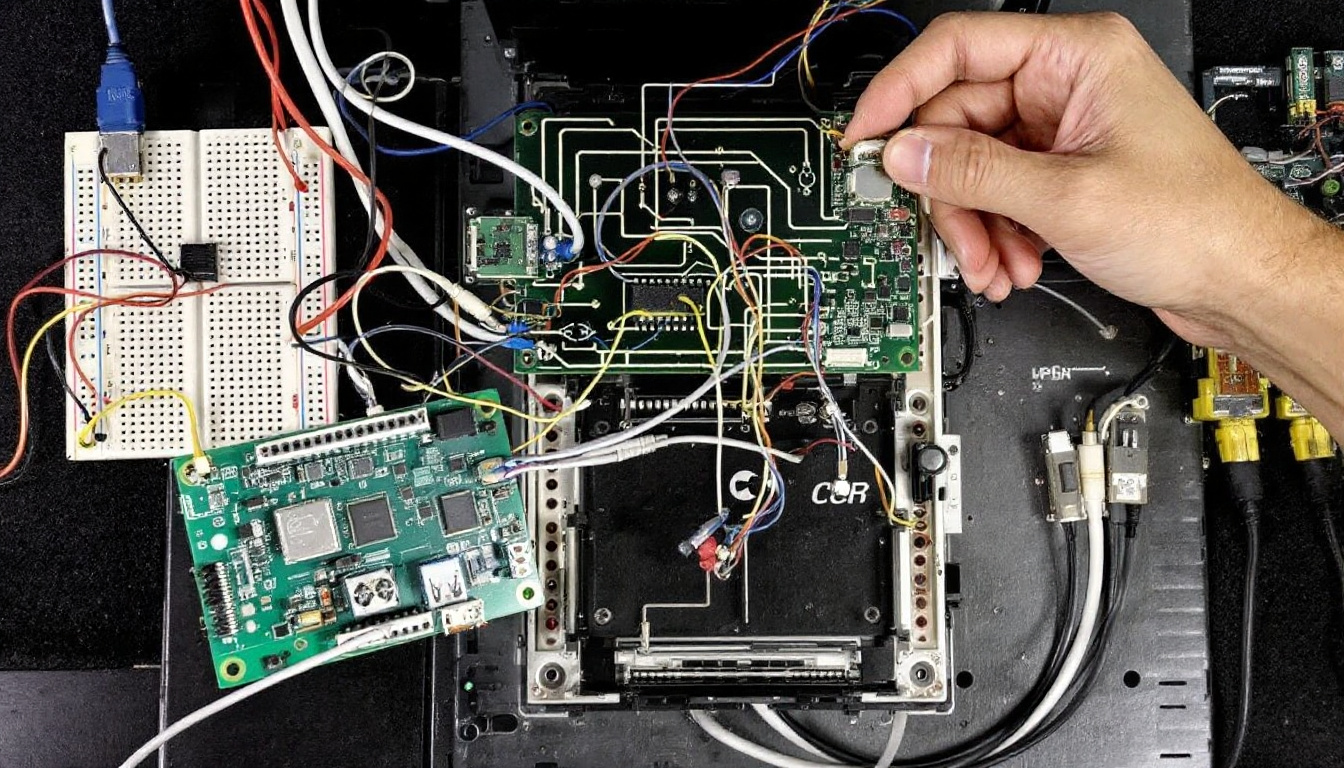

Soldering is like the glue that holds a circuit board together—but instead of adhesive, it uses a metal mixture to bond components securely. This process is critical for ensuring that electronic parts both stay in place and function correctly.

Why is soldering essential?

- Connection Stability: Soldering fixes components in place, preventing them from moving despite vibrations or accidental bumps.

- Efficient Current Flow: The molten solder creates a reliable bridge for electricity to flow between traces and components.

- Durability and Longevity: Proper soldering protects the circuit from wear and tear over time, extending its lifespan.

There are two main methods of soldering:

- Hand Soldering: Used for small-scale production or repairs, where skilled technicians use soldering irons to connect components.

- Wave Soldering: A high-efficiency process for mass production, where molten solder flows over the board and simultaneously attaches multiple components.

Poor soldering can result in “cold joints,” where partial connections fail to carry electricity, potentially causing malfunctions. Thus, great care is taken to ensure every connection is solid and precise.

For further insights into how these processes come together to form functioning circuit boards, dive into this comprehensive look at electronics.

Applications of Circuit Boards in Everyday Life

Circuit boards are integral to nearly every aspect of our daily routines. From simplifying communication to enabling sophisticated technological advancements, their role cannot be overstated. These intricate boards empower various devices and systems, ensuring they operate efficiently and effectively.

Circuit Boards in Consumer Electronics

Modern consumer electronics owe their functionality to the intricate designs of circuit boards. These boards act as the central nervous system for gadgets, allowing components to communicate seamlessly for optimal performance.

Circuit boards in smartphones are prime examples of advanced miniaturization. Within these compact devices, circuit boards enable features like touchscreen response, high-speed processors, and wireless connectivity. Similarly, laptops rely on multi-layer boards to support complex operations, from multitasking to gaming and video editing. Smart home devices, such as thermostats, speakers, and security systems, integrate boards to process commands and interact across ecosystems, ensuring smooth user experiences.

For more examples of electronics integrating circuit boards, explore this site.

Specialized Circuit Boards in Advanced Technology

In advanced technology, circuit boards fulfill crucial roles by enabling operations in demanding and high-stakes environments. These specialized boards are engineered for precision, durability, and efficiency.

In satellites, circuit boards manage data transmission, power regulation, and operation of onboard systems, ensuring reliability throughout harsh conditions in space. The military employs highly durable boards in equipment like guided systems and reconnaissance technology, where even minor malfunctions cannot be tolerated. High-performance computers, such as those used in scientific research or trading systems, depend on multi-layered PCBs to handle enormous processing loads while maintaining speed and accuracy.

These examples highlight the versatility of circuit boards, demonstrating their capabilities from facilitating daily convenience to addressing complex scenarios in the most challenging environments. Each system, no matter how advanced, requires a reliable framework built on these boards to perform seamlessly.

Emerging Trends & Future of Circuit Boards

As electronics become increasingly complex and integrated into daily life, circuit boards continue evolving to meet new demands. From sustainability to miniaturization for IoT applications, the innovations shaping circuit boards today will define the tech of tomorrow.

Environmentally Friendly Circuit Boards

The rise of green technology in circuit boards highlights a growing commitment to sustainability. Recyclable materials and biodegradable substrates are becoming more common as manufacturers strive to reduce waste and environmental impact.

- Recyclable Components: Modern boards often use materials like aluminum and tin that can be efficiently recycled, minimizing e-waste.

- Biodegradable Boards: A new generation of circuit boards employs organic materials, such as cellulose or hemp fibers, to create biodegradable substrates. These boards decompose naturally when discarded, offering an eco-friendly alternative.

- Lead-Free Soldering: Advances in soldering technologies have made it possible to eliminate harmful materials like lead, further aligning circuit boards with sustainable practices.

Efforts to make circuit boards more environmentally friendly also include optimizing manufacturing. Processes now focus on energy-efficient production and reducing chemical waste, contributing to the industry’s overall green initiatives. For more on similar trends influencing design, explore this detailed post on emerging PCB technologies.

The Rise of IoT and Smart Devices

The Internet of Things (IoT) is revolutionizing how circuit boards are designed. As consumer products become “smarter,” engineers are tasked with creating smaller and more efficient boards to meet these products’ unique requirements.

- Miniaturization: Advances in circuit board manufacturing allow components to be packed into smaller spaces without sacrificing performance. This trend is critical in products like wearable devices, which rely on compact designs to function seamlessly.

- Wireless Connectivity: IoT devices depend on consistent connections, pushing for improved antenna integration and reduced latency through optimized PCBs.

- High-Density Interconnects (HDI): These advanced boards allow for intricate designs and multiple layers, enabling faster data transmission and higher functionality in devices like smart thermostats, fitness trackers, and even autonomous vehicles.

Circuit boards are also playing a significant role in creating connected ecosystems. Take smart home systems as an example, where boards serve as the backbone for devices to communicate via platforms like Wi-Fi or Bluetooth. For a deeper dive into how digital evolution is shaping consumer products, check out this resource on Digital Product trends.

The future of circuit boards is inseparably tied to innovations like IoT and sustainable materials. As electronics march forward, these trends are setting the stage for smarter, greener, and more efficient technologies. For more insights, see this overview of emerging PCB practices.

Conclusion

Circuit boards are the silent architects behind countless technologies shaping our lives. By understanding their structure and function, one gains a deeper appreciation for their essential role in everything from consumer electronics to advanced innovations.

From ensuring seamless operation to enabling rapid technological advancements, these boards connect the modern world in ways that often go unnoticed. To explore more on how electronics impact everyday life, visit this guide.

Recognizing the complexity involved in circuit boards fosters not only technical awareness but greater appreciation for the systems we rely on. Whether in a smartphone or a spacecraft, circuit boards form the foundation of progress and innovation. Explore emerging trends and the broader impact of technology here.